Protective clothing material - Mario Groß

Comparison between Spunbond/Meltblown/Spunbond (SMS), Microporous Film (MPF) and Tyvek®

Material structure

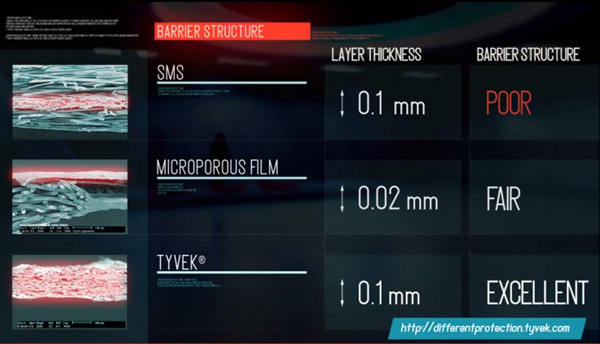

Spunbond/Meltblown/Spunbond (SMS) is a material made from combining brittle and extremely thin meltblown polypropylene (PP) layers (meltblown) as a barrier layer between two layers of PP spunbond. The barrier layer has a thickness of 0.1 mm. Thanks to its relatively large pores, the material is highly permeable to air and water vapour, however it provides a less effective particle barrier when compared to other materials.

Microporous film (MPF) consists of a polyethylene (PE) foil with microscopically small pores that is applied on top of a spunbond base layer. The PE foil is the barrier layer. It has a thickness of only 0.02 mm and has a very low resistance to abrasion.

DuPont™ Tyvek® is made from very fine, spun, continuous high-density polyethylene (HD-PE) fibres, which are compressed using heat and pressure into a non-woven material. The barrier (0.1 mm) is inherent to the particular structure of the material and provides a high degree of protection against airborne particles and numerous water-soluble inorganic chemicals. The material is not only extremely durable - Tyvek® has a high degree of resistance to tearing, ripping and abrasion - but is also light, soft and permeable to air and water vapour, providing a high degree of wearing comfort. No fillers, binding agents, softening agents or silicones are used during its manufacture.

Figure 1: Comparison of the material structures of SMS, MPF and Tyvek®. The effective barrier layer is indicated in pink.

Protection against chemicals

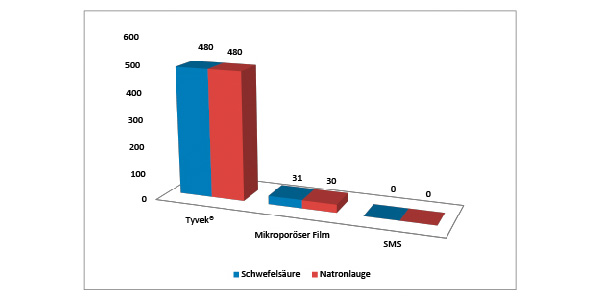

Permeation refers to the penetration of liquids or gases through the clothing material at the molecular level. Permeation tests done in accordance with EN ISO 65291 provide indications of the long-term behaviour of a material (normal test duration: 480 minutes), and are therefore more useful in practice than penetration tests, for which the normal duration is one minute.

An external laboratory commissioned by DuPont measured permeation times for Tyvek®, SMS (DuPont™ ProShield® 10) and MPF (DuPont™ ProShield® 30) for an 18% sulphuric acid and a 40% sodium hydroxide solution, two substances used as standard in the industry. The tests were carried out in a depressurised atmosphere at a room temperature of 23 °C.

A 40% sodium hydroxide and an 18% sulphuric acid solution were selected for the permeation test, which are two chemicals that are used as standard in the industry. The results reflect the minimum values for the various test samples. Tyvek® achieved a permeation time for both substances of more than 480 minutes (Figure 2). The microporous film laminate did not achieve a result like that of Tyvek®, although the sodium hydroxide was diluted to a concentration of 10 % for the tests. In practice, this means that workers are not sufficiently protected against once-off or longer-term contact with these test substances. Due to its more open structure, SMS does not provide much protection against permeation of these chemicals.

Figure 2: Result of permeation tests on various protective clothing materials with 40% sodium hydroxide solution (diluted to a concentration of 10% for part of the tests) and 18% sulphuric acid. [Blue = sulphuric acid, red = sodium hydroxide.]

Protection against particles

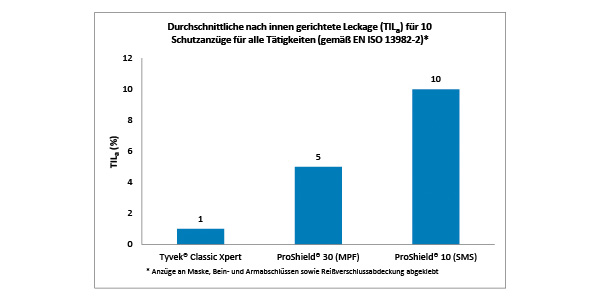

The average inward leakage (TILa) according to EN ISO 13982-22 is the unit of measurement for the level of barrier protection against particles of an item of protective clothing. A low value indicates a strong particle barrier. If one compares, for example, Tyvek® Classic Xpert with other Type 5 protective materials made from MPF and SMS, the Tyvek® sample has significantly lower average inward leakage, at 1%. The Type 5 standard allows for a value of up to 15% for 8 out of 10 samples tested (Figure 3).

Figure 3: Average inward leakage of various Type 5 protective suits (TILa, average value for 20 items in percentages for all activities in accordance with EN ISO 13982-2). Suits taped at mask, leg and arm seams and zip fastener covering.

Propensity for formation of lint

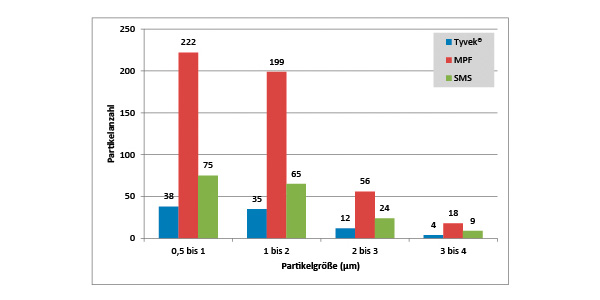

Due to its particular material structure, Tyvek® is extremely low lint and is therefore suitable for use in environments with high cleanliness requirements, e.g. in laboratories or for lacquering vehicles or aeroplanes.

A materials test carried out by an independent testing institution in accordance with BS 6909 found that Tyvek® released significantly fewer particles than MPF or SMS.

Figure 4: Propensity for formation of lint of protective clothing materials (average number of particles in 17 l of air). Procedures for formation and measurement of lint particles generated in the air flow for dry tissue (in accordance with BS 6909).

Wearing comfort

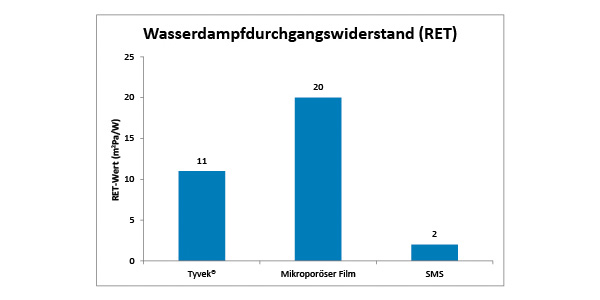

The RET-Test (resistance to evaporative heat loss of a textile) measures how resistant a textile material is to water vapour. The lower the RET value, the more breathable the material. Compared to Tyvek® and SMS, MPF has the highest value. Due to its open structure, the breathability of SMS is very high, but it provides a low level of barrier protection against particles and chemicals. In contrast, Tyvek® provides a balanced combination of breathability and protectiveness.

Figure 5: Resistance to water vapour (RET value) of various protective clothing materials. The value given is the average value for 5 suits tested.

Mario Groß

DuPont Protection Technologies

Customer And End User Advisor

Deutsch

Deutsch

English

English