Service for safety cabinets

Testing, maintenance and repair of microbiological safety cabinets and safety cabinets for cytostatics

Servicing safety cabinets and LAFs (almost all manufacturers) is our core competence.

Regular testing of your workbench is the only way to ensure safety and functionality and comply with legal requirements! We carry out commissioning and routine tests for you in accordance with DIN 12980, DIN EN 12469, VDI 2083 ff. and DIN EN ISO 14644 ff. depending on relevance and agreement.

Of course, you will receive comprehensive documentation for all tests.

Installation, testing, maintenance & repair of:

- Safety cabinets for cytostatics

- Microbiological safety cabinets

- Product protection safety cabinets

- LAF (LaminarAirFlow) devices

- Isolators

Our highlights:

- Service for own and third-party cabinets

- Special installation in laboratories that are difficult to access

- One partner for all workbenches and ventilation

- Connection to exhaust air systems

- Fast repair due to availability of spare parts

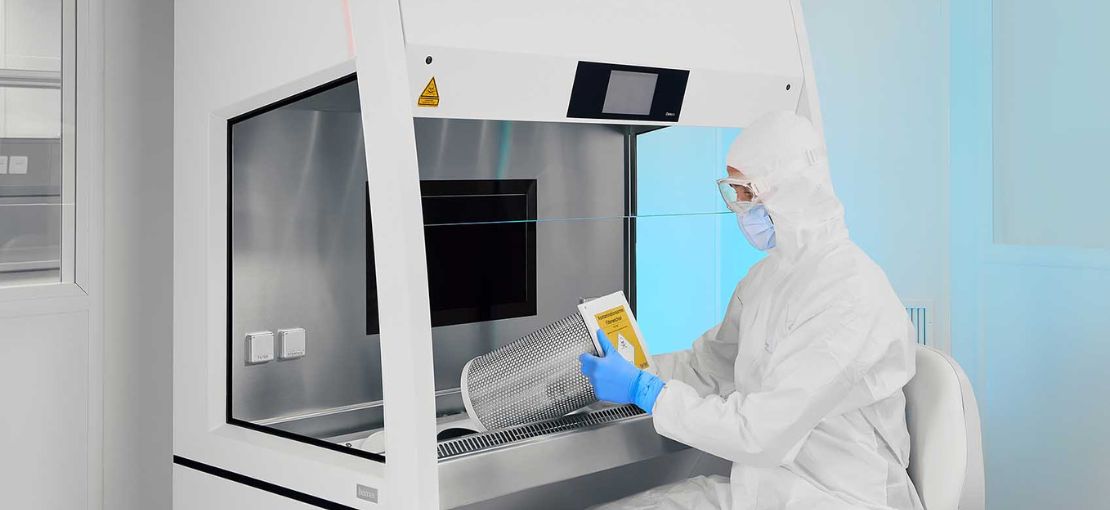

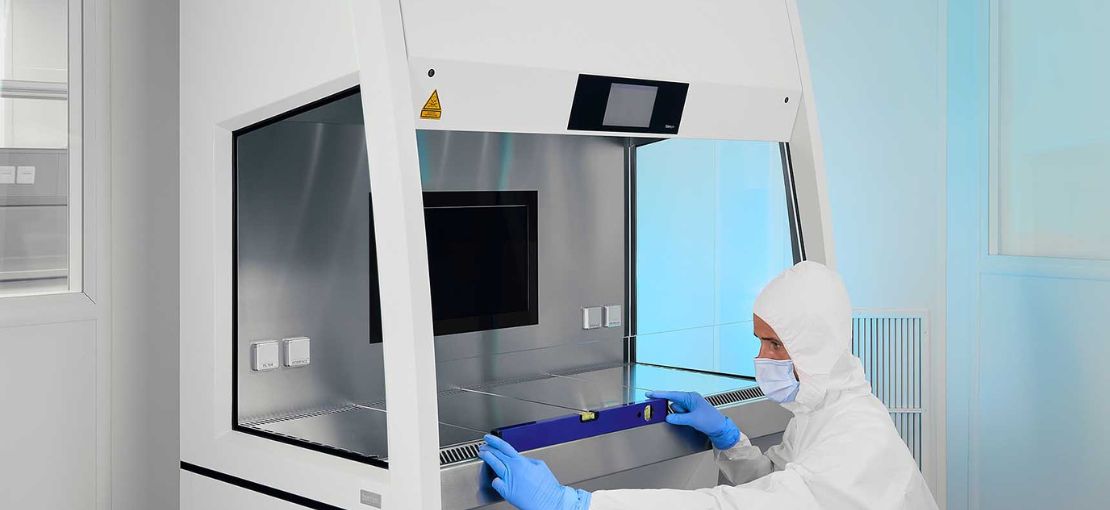

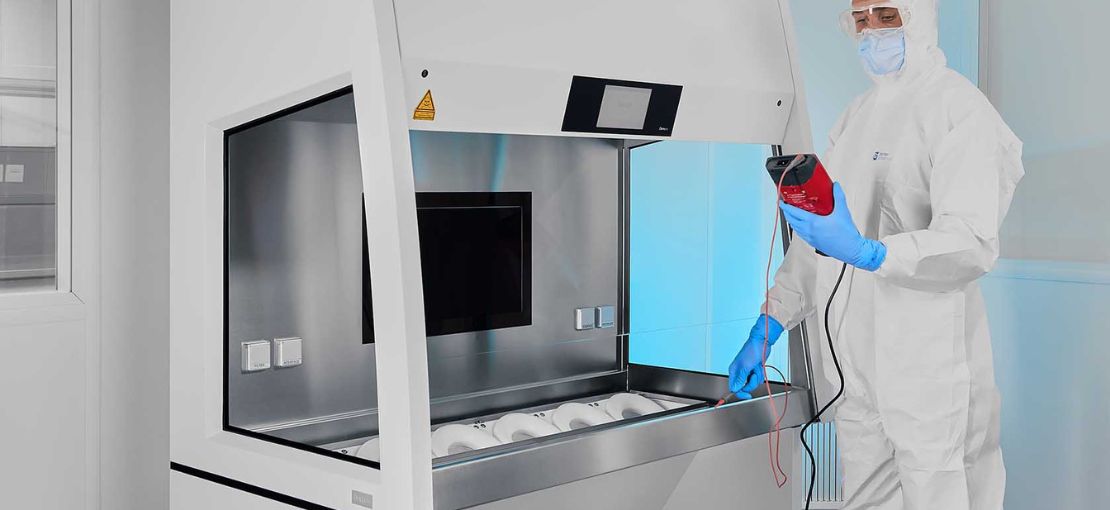

Insights into our service

Please be patient for a moment!

Deutsch

Deutsch

English

English